Fish Shred Production Line Manufacturer

Thai BENTO fish fillets, Chinese Fragrant fillet or Surimi Fish Snack、Malaysian Gindaco

TsungHsing Food Machinery is a fish shred production line machine manufacturer and supplier. TsungHsing Food Machinery (TSHS) provides snack foods through the processing of production equipment for the processing of surimi as the main raw material. It is a derivative application of fish products.

The Pollack Fish Snack can be said to be a classical Taiwanese snack, and many people have fond childhood memories of it. It is said that the pollack fish snack was invented by the Japanese and later passed to Taiwan. It was considered a high class import food that gradually became an important product in the surimi processing industry in Taiwan. Related applications are widely used in various Asian countries.

Capacity

- In case of different products, please contact our business department and our staffs will be serving you.

Features

- The product is made from surimi as the main raw material, and different processing methods and processes are derived. Different product applications are available. Such as Thailand's well-known BENTO fish fillets, Japanese natori surimi fish snack, Chinese fragrant fillet or surimi fish snack, Malaysian gindaco.

- TSHS provides automatic production of the Fish Shred Production Line with stable quality control. And the design emphasizes: the equipment is easy to operate and made of stainless steel, which compliances food hygiene and safety. Manpower economizing, and increasing efficiency.

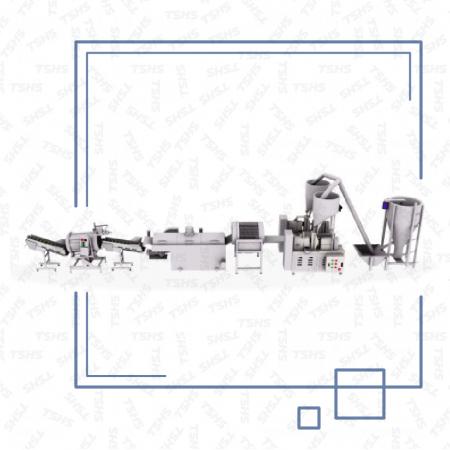

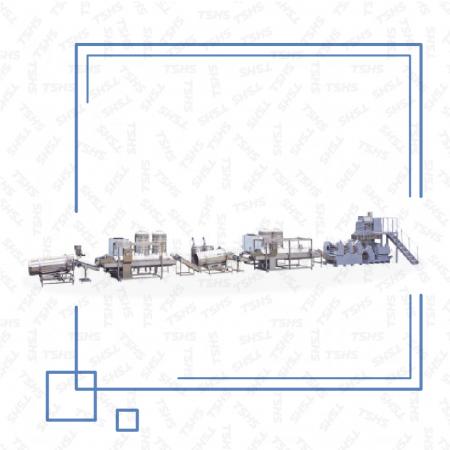

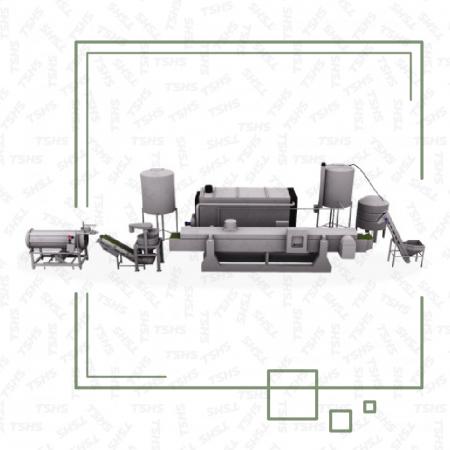

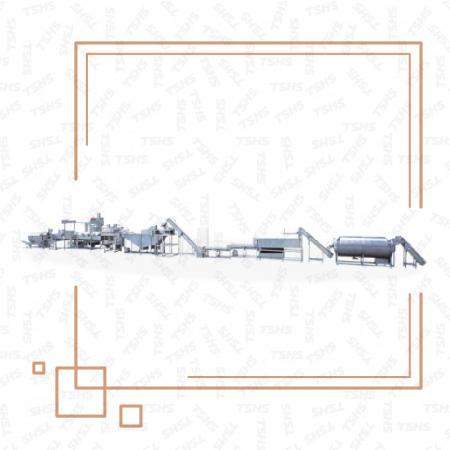

Flow Chart

Ten operation works: Surimi Mixing→ Ejecting→ Pre-baking→ Drying→ Dipping→ Baking→ Cutting→ Shredding.

Product Features

- The raw materials of fish shred are mainly surimi, wheat flour, sugar, salt, etc., and are processed into high speed crushing strainer, beating, seasoning, stirring and other processes to make surimi raw materials. The surimi is then extruded into a sheet shape through a ejector, dried, dipped, air-dried, and then cut into a filament by a wire cutter after being cut and cooled by a high-temperature baking to complete the production.

SPECIFICATIONS

1. Surimi Raw Material Mixing

1. Surimi Raw Material Mixing

The surimi flour and the seasoning are added to the high speed crushing strainer container for cutting and stirring, so that the surimi is more meticulous and tasty, and the machine is not easily blocked in production.

High Speed Crushing Strainer

(1)The pot body 304# is made of stainless steel, and the aluminum alloy is used for the lid and the discharge port.

(2)The cutter is made of SUS420 stainless steel.

(3)Horsepower Requires 50H.

2. Forming Machine

2. Forming Machine

The stirred fish paste is pumped into the storage drum of the ejector by a screw pump, and the surimi is slightly matured by heating in a molding machine on a molding machine that is uniformly extruded to the fish production equipment via a roller, and the scraper is used. Scrape the fish fillets into the pre-baked oven.

(1)Using infrared heater.

(2)The roller of the ejector is made of 304# stainless steel.

(3)The inside of the roller is cooled by circulating cooling water.

(4)The wheel width of 1050mm can simultaneously extrude two pieces of fish fillets.

3. Pre Baking M/C

3. Pre Baking M/C

The pre-baking machine of the fish shred production equipment of TSHS is heated by gas infrared fire tube, which can instantly remove the moisture of the surimi skin and prevent it from sticking to the mesh belt when it enters the next process.

(1)Using stainless steel aheap balanced conveyor belt.

(2)Using infrared heater.

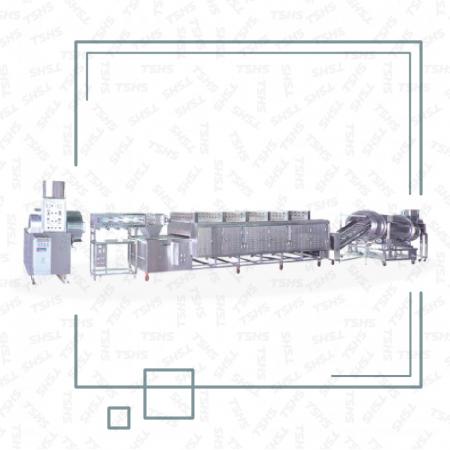

4. Dryer

4. Dryer

The Dryer of the Fish Shred Production Line of TSHS is made of stainless steel according to the requirements of food hygiene regulations, and the heating system uses a gas direct fire burner, high heating efficiency, energy clean and non-polluting products. The hot air circulation system uses a stainless steel turbo-type windmill to be placed in a crosswise manner so that the hot air is uniform and has no-escape corner, so that the surimi can be evenly heated while being dried to achieve the best quality.

11 layers gas operation - Conveyor Type Auto Dryer(WS-206)

1.1 Outer diameter Length 12295 x Width 2435 x Height 3500 mm.

1.2 Inner diameter Length 10000 x Width 1342 x Height 2590 mm.

(1)Conveyor uses TECO Motor + Reducer 3HP.

(2) Air Circulating Fan: Using TECO Motor 2HP.

(1)The whole equipment is made of stainless steel according to the requirements of food hygiene regulations.

(2)The heating system uses a gas direct fire burner, high heating efficiency, energy clean and non-polluting products.

(3) The hot air circulation system uses a stainless steel turbo-type windmill to be placed in a crosswise manner so that the hot air is uniform and has no-escape corner, so that the surimi can be evenly heated while being dried to achieve the best quality.

5. Dipping M/C

5. Dipping M/C

The dipping machine of the fish shred production equipment of TSHS is made of stainless steel for ensuring the sanitary condition of the whole product. And through the special design of the company, using the vertical wrap system and food grade steel scraper, the excess sauce can be scraped off, and the sauce can be evenly spread on the fish fillet to make the product taste the best.

(1) The whole equipment is made of stainless steel according to the requirements of food hygiene regulations.

(2) Scraping off the excess sauce, and spread the sauce evenly on the fish fillet to achieve the best taste by the special design, which uses the vertical jam system with food grade steel scraper.

6. Hanging Air Dryer

6. Hanging Air Dryer

The main feature of the hanging air dryer of the Fish Shred Production Line of TSHS is to slowly deepen the sauce into the inside of the fish fillet to increase the flavor by using the dipped fish fillet and the surface sauce in the natural air-dry mode.

7. Infra-Red Conveyor Oven

7. Infra-Red Conveyor Oven

The gas infra-red conveyor oven of the fish shred production equipment is heated and baked by using the infrared ray, and the radiant heat of the infrared rays directly penetrates the fish fillets to achieve rapid ripening and foaming to increase the taste of the product.

LIVE SHOT

| raw material | Production process |

|  |

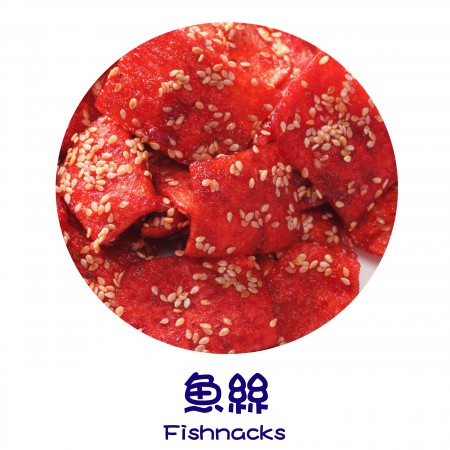

| Finished Product | |

|  |

LAYOUT

Applications

- Fish Snacks, Dried Fish Fillet, Black Sesame Sandwich Wire

- Related Products

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsGrain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNuts Processing Production Line Manufacturer

Nut products are widely embraced and cherished across global snack food cultures, whether in Western...

DetailsNoodle Snacks Production Line Manufacturer

TsungHsing Food Machinery is a noodle snacks production line machine manufacturer and supplier....

DetailsGreen Pea Production Line Manufacturer

TsungHsing Food Machinery is a green pea production line machine manufacturer and supplier....

DetailsPotato Chips Production Line Manufacturer

TsungHsing Food Machinery is a potato chips production line machine manufacturer and supplier....

DetailsPellet Snacks Production Line Manufacturer

TsungHsing Food Machinery is a pellet snacks production line machine manufacturer and supplier....

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

DetailsBanana Chips Production Line Manufacturer

TsungHsing Food Machinery is a banana chips production line machine manufacturer and supplier....

Details- Videos

- Finished Product Gallery

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Fish Shred Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Fish Shred Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 58 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.