Nuts Processing Production Line Manufacturer

Nut Processing, Bean Processing, Nut Baking, Bean Baking, ถั่วลันเตาทอด, ถั่วลันเตาเคลือบวาซาบิ, ถั่วปรุงรส, ถั่วปรุงรสหลายชนิด, ถั่วปากอ้าทอด, ถั่วลิสงเคลือบ, コーティングピーナッツ

Nut products are widely embraced and cherished across global snack food cultures, whether in Western or Eastern traditions. Nut-based processed snacks are considered one of the origins of modern snack foods, evolving from the earliest simple roasting and frying methods to more diverse innovations such as coated nuts, battered nuts, and garlic-flavored peanuts. Using commonly available agricultural products like peanuts, green peas, cashews, and almonds as raw materials, these are fried, dried, or roasted to perfection before being seasoned to create delicious snacks loved by people of all ages. Bean-based products on the market can be categorized by final product type into coated and non-coated varieties, or by the cooking process into fried or roasted products. The diversity of processing methods and seasoning options makes it easy to develop new products, making this category a highly promising market segment for snack food manufacturers.

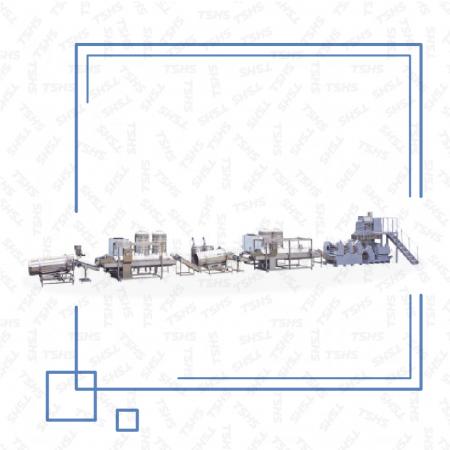

TsungHsing(TSHS) specializes in manufacturing complete production line equipment for nut processing, offering comprehensive solutions from raw material handling to frying, baking, roasting, seasoning, and coating. Our equipment supports the production of nut snacks that are popular in global markets, catering to diverse cultural and consumer needs. Key processing methods include frying, roasting, drying, and baking, further divided into coated and non-coated options, providing food manufacturers with flexible and comprehensive processing choices.

Features Of Nuts Processing Production Line

1. Raw materials are easily sourced, production processes are versatile, equipment is simple to operate, and the flavors can range from sweet to savory, making it a highly scalable market.

2. Supports both small-scale semi-automated production and large-scale continuous operations, ensuring stable quality and compliance with food hygiene standards.

3. Distinctive product features with high production technology value.

4. Production processes can be adjusted based on specific requirements.

5. Production capacity can be tailored to meet customer needs.

6. Diverse product range.

7. Equipment is simple and easy to operate.

Process

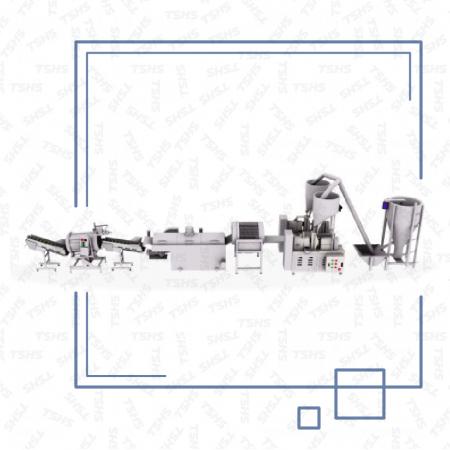

The nut processing production line adopts different processing methods depending on the raw materials, such as coated or non-coated processing, as well as materials requiring soaking before processing or direct processing without soaking. Through the production process, raw materials such as nuts and legumes undergo surface treatment, product curing, and seasoning. Generally, the processing methods can be categorized into pure processing (focusing solely on curing raw materials without any additional components) and enhanced processing methods (such as sugar-coating or powder-coating). For example, the typical process for powder-coated peanuts is as follows: Powder-Coated Peanuts:Raw shelled peanuts → Shelling → Kernel selection → Screening → Roasting → Powder coating → Baking → Seasoning → Drying → Cooling → Packaging(This is the basic configuration. For special requirements, please contact us via email.)

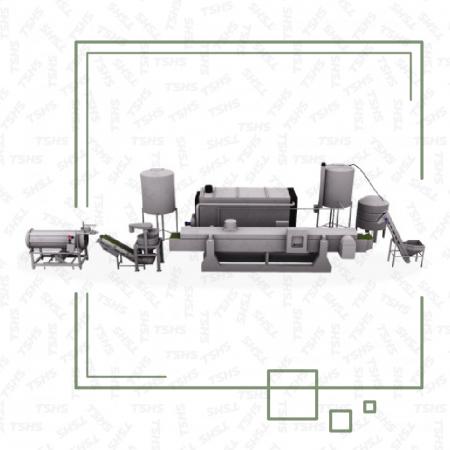

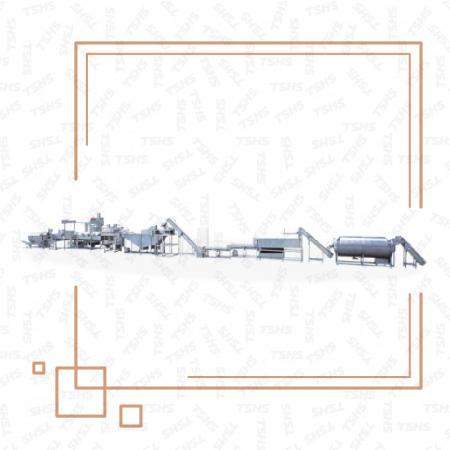

Machine Layout

Equipment Information of Nuts Processing Production Line

1. Roasting Machine

The roasting machine is designed for processing nuts and legumes, making it ideal for uniformly roasting various raw materials such as peanuts, cashews, almonds, pistachios, soybeans, and red beans. It precisely controls heating temperature and time, ensuring optimal curing and aroma release. This equipment enhances product texture, extends shelf life, and retains nutritional value, making it highly suitable for food processing plants, snack food manufacturers, and health food producers. The machine is available in different specifications, with capacities of 60 kg or 180 kg per batch, and dimensions ranging from 243 cm to 295 cm in length, 118 cm to 134 cm in width, and 192 cm to 222 cm in height. It weighs 450 kg or 680 kg, operates with 1HP or 2HP motors, and can be customized to meet specific production line requirements.

2. Powder Coating Machine

The powder coating machine is primarily used for evenly applying powdered seasonings to the surface of food products, making it suitable for processing items such as fried chicken nuggets, chicken wings, French fries, onion rings, potato chips, and nuts. The machine achieves uniform seasoning distribution through drum rotation, ensuring consistent flavor and enhancing the taste and quality of the final product. Its flexibility allows it to accommodate various sizes and shapes of food items, making it an essential seasoning equipment for snack food, frozen food, and fast food production lines. It helps improve production efficiency while ensuring product consistency. The specifications of the powder coating machine are as follows: a capacity of 24 kg per batch (scalable), a body length of 98 cm, a width of 88 cm, a height of 140 cm, a weight of 95 kg, and a motor power of 1HP. Additionally, the product specifications can be customized according to production line requirements, providing flexibility to meet diverse production needs.

3. Roaster

Roaster is specially designed for food processing, suitable for roasting and toasting raw materials such as nuts, coffee beans, sesame seeds, grains, and spices. This equipment evenly heats the materials, promoting moisture evaporation and releasing internal aromas to achieve optimal curing and flavor enhancement. It offers precise temperature and roasting time control based on the characteristics of different raw materials, preventing over-roasting or charring and ensuring stable product quality. Widely used in food processing plants, bakeries, and health food manufacturing, the flat roasting machine is ideal for large-scale production needs, significantly improving efficiency and product competitiveness. The machine features a high-spec design with dimensions of L4695 × W3000 × H1653 (mm). All components in contact with food are made of SUS304 stainless steel, meeting food-grade hygiene standards, ensuring durability, and making cleaning easy. It is equipped with a 5HP motor reducer, providing powerful and stable operation. The heating system includes 16 infrared gas burners (model WS-3202) on the top and subsidiary gas burners below, delivering uniform and efficient heating performance. The machine has a single-batch capacity of approximately 60 kilograms, meeting the demands of high-volume production and making it a high-performance roasting solution for the food processing industry.

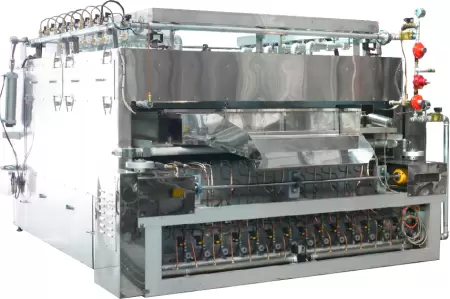

4. Continuous Fryer

The continuous fryer is a high-efficiency frying machine designed for large-scale food processing, ideal for the continuous frying of various products such as potato chips, fried chicken nuggets, shrimp crackers, nuts, tofu, and other snack foods. This equipment ensures uniform frying, delivering a crispy exterior and tender interior while offering precise temperature control to prevent over-frying or product inconsistency. Its continuous design enhances production efficiency, shortens processing cycles, and seamlessly integrates with other production line equipment, making it suitable for automated large-scale production needs. The fryer not only improves food quality but also reduces production costs, making it a core piece of equipment in the frozen food, snack, and fast-food manufacturing industries. Specifications for the fryer can be customized to fit specific production line requirements.

5. Liquid Spraying Machine

The liquid spraying machine is a high-efficiency device designed specifically for food processing, offering a range of advanced features. The machine utilizes a water-jacket design with a hot water circulation system to maintain stable and uniform liquid temperatures. It is equipped with internal stirring blades to prevent sedimentation of solid particles, ensuring consistent liquid quality. The spray gun is designed with versatility in mind, allowing adjustments to accommodate different fluid characteristics and meet diverse production needs. This machine is ideal for processes such as food seasoning, liquid coating, and surface treatments, making it particularly suited for the precise application of sauces and seasoning liquids. It ensures product uniformity and consistency in flavor and texture. Its flexible design makes it highly applicable in food processing, seasoning manufacturing, and other liquid handling industries, providing a reliable solution for improving production efficiency and product quality.

6. V-type Mixer

The V-type mixer is a high-performance mixing device that achieves optimal mixing results through the cross-blending and separation motion created by the rotation of its V-shaped chamber. The machine operates most efficiently at 30%–40% of its full capacity and is available in materials such as mild steel or stainless steel to meet various requirements. Optional features include the addition of internal mixing blades or internal polishing to further enhance mixing efficiency and product quality. The equipment is equipped with an automatic positioning and discharge system, making it highly convenient and efficient to operate. The V-type mixer is ideal for mixing lightweight powders, such as pigments, dyes, and pharmaceuticals, and is widely used in industries including chemicals, pharmaceuticals, food, and other powder-related processing fields. Its high-efficiency mixing capabilities ensure uniformity and stability, making it an excellent choice for powder mixing applications.

7. Kernel Sorting Machine (screening machine)

The kernel sorting machine (screening machine) utilizes an innovative three-dimensional vibrating screen design, offering a compact and durable structure with low noise, providing a quiet and efficient screening solution for food processing. Its design not only extends the lifespan of the screen but also increases the available screening area while minimizing material loss and waste during processing. The machine can accommodate up to five layers of screens, allowing for the separation of up to six different material sizes in a single operation, significantly enhancing screening efficiency. It is primarily used for screening and grading granular materials such as nuts, legumes, and grains, ensuring precise classification of materials by size. This equipment is widely applicable in food processing, agricultural product handling, and other industries requiring high-efficiency screening solutions.

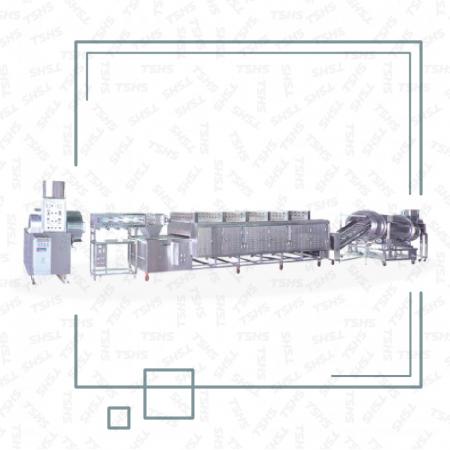

8. Conveyor Dryer

The continuous conveyor dryer is a high-performance drying machine specifically designed for large-scale production. It features a continuous conveyor system and utilizes hot air circulation to evenly dry materials, ensuring consistent product quality. The design allows for adjustments to conveyor speed and drying temperature based on the characteristics of the materials, making it adaptable to various production requirements and significantly improving drying efficiency. Built with a durable structure and constructed from food-grade stainless steel, the equipment meets hygiene and safety standards. The continuous conveyor dryer is widely used in industries such as food processing, agricultural products, and chemical materials, making it suitable for drying products like snack foods, nuts, seasonings, and grains. With its stable conveying and drying performance, the machine effectively reduces production cycles and increases throughput, making it an indispensable core component of automated production lines.

9. Air-flow Cyclone Dryer

The air-flow cyclone dryer is a high-efficiency, rapid drying device that uses air-flow and cyclone separation technology to deliver hot air at high speeds into the drying chamber, enabling instant drying of materials. With its compact structure and small footprint, this equipment can handle large-scale drying operations in a short time, making it particularly suitable for high-moisture granular materials. During the drying process, materials are fully exposed to the hot air, ensuring rapid moisture evaporation while avoiding overheating or clumping. The machine is constructed from food-grade stainless steel, meeting hygiene standards, and can be customized to specific requirements. The cyclone air-flow dryer is widely used in industries such as food processing, biotechnology, pharmaceuticals, and agricultural product handling. It is especially suited for drying products like nuts, legumes, animal feed, insects, herbal medicines, and other granular items. Its rapid and efficient drying performance not only enhances production efficiency but also ensures consistent product quality.

10. Seasoning Drum

The seasoning tumbler is a high-efficiency seasoning device specifically designed for food processing. Featuring a rotary design, it ensures uniform mixing of seasonings with the product. The equipment is constructed with a durable structure, typically made from food-grade stainless steel, making it both robust and easy to clean while adhering to hygiene standards. The tumbler's capacity and tilt angle can be adjusted to meet the requirements of various products, offering simple and flexible operation suitable for a wide range of production line configurations. Equipped with variable frequency speed control, it allows precise adjustment of the rotation speed, ensuring even seasoning distribution while preventing damage to the materials. The seasoning tumbler is widely used for seasoning a variety of food products, such as potato chips, nuts, legumes, peanuts, and other snack foods. Its high-performance mixing capabilities not only enhance production efficiency but also ensure seasoning consistency and product quality.

Capacity

- 200-1000 kg/hr (Depending on the desired frying time and product density.)

Applications

- Dry-Roasted Peanuts, Coated Peanuts, Fried Peanuts, Dry-Roasted Cashews, Fried Cashews, Dry-Roasted Almonds, Fried Almonds, Fried Broad Beans, Fried Green Peas, Coated Green Peas, Coated Legumes, Crispy Nuts

- Coated Peanuts

- Coated Peanuts

- Coated Peanuts

- Fried Green Pea

- Fried Peanuts

- Fried Peanuts

- Broad Bean

- Cashew

TSHS provides the consultant food solutions

Tsung Hsing Food Machinery is a food machine manufacturer and supplier of Nuts Processing Production Line. From powder coating, roasting, frying, and seasoning. We can provide complete Nuts, Peanuts, Beans Processing production line solutions.

If you have a Nuts Processing production machine requirement, please fill out the inquiry form below. We will contact you as soon as possible.

CASE STUDY

- Related Products

Corn Curl Production Line Manufacturer

The raw material of Cheeto corn curl production line is corn that is easier to obtain around...

DetailsGrain Puff Production Line Manufacturer

Our corn curl production line is fully automated, it is easy to operate and manpower saving....

DetailsNoodle Snacks Production Line Manufacturer

TsungHsing Food Machinery is a noodle snacks production line machine manufacturer and supplier....

DetailsGreen Pea Production Line Manufacturer

TsungHsing Food Machinery is a green pea production line machine manufacturer and supplier....

DetailsPotato Chips Production Line Manufacturer

TsungHsing Food Machinery is a potato chips production line machine manufacturer and supplier....

DetailsFish Shred Production Line Manufacturer

TsungHsing Food Machinery is a fish shred production line machine manufacturer and supplier....

DetailsPellet Snacks Production Line Manufacturer

TsungHsing Food Machinery is a pellet snacks production line machine manufacturer and supplier....

DetailsFish Murukku Production Line Manufacturer

TsungHsing Food Machinery is a fish murukku production line machine manufacturer and supplier....

DetailsBanana Chips Production Line Manufacturer

TsungHsing Food Machinery is a banana chips production line machine manufacturer and supplier....

Details- Videos

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Nuts Processing Production Line Manufacturer Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Nuts Processing Production Line Manufacturer supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 58 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.