How to produce classic potato chips?

"The Production Process and Secrets Behind the Deliciousness of Potato Chips"

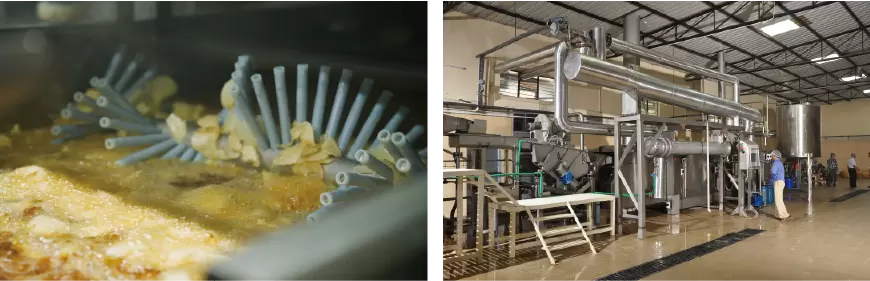

Potato chips are a globally beloved snack, renowned for their crispy texture and showcasing intricate craftsmanship. The production process begins with selecting potatoes with moderate starch content. After washing, peeling, and slicing, the potatoes are soaked in cold water to reduce surface starch, ensuring an even, crispy fry. Frying is the key step, requiring precise control of the oil temperature between 180°C and 200°C and careful timing to achieve the perfect golden color while avoiding burnt or soggy chips. This process retains the natural aroma of potatoes. Seasoning adds diverse flavors, from classic salted to barbecue, seaweed, honey mustard, and more, catering to various tastes.

Premium brands prioritize quality control throughout production to ensure consistent freshness and texture in every bag. Each step of the process directly impacts the final product's quality, which is why potato chips remain a timeless snack favorite.

"Where Does This Crispy Delight Come From?"

The history of potato chips is fascinating, dating back to 1853 in New York, USA. Legend has it that a customer complained about thick and insufficiently crispy potato slices at a restaurant. In response, chef George Crum sliced the potatoes extremely thin, fried them until crispy, and sprinkled them with salt. To everyone's surprise, the unique thin and crispy texture was a hit and quickly became a signature local snack. Over time, potato chips evolved from a regional specialty into a globally celebrated classic snack, incorporating diverse flavors inspired by local tastes to become an irresistible treat.

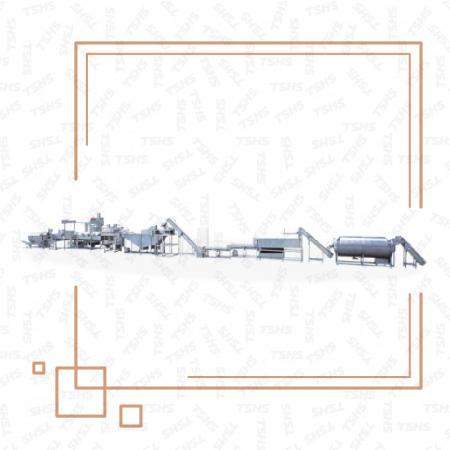

"High-Efficiency Automated Potato Chip Production Line: The Best Choice for Energy Savings, Labor Reduction, and Superior Quality"

TSHS Food Machinery's potato chip production line features a fully automated system, high efficiency, and excellent quality to meet varying production demands. With precision control technology, every process is stable and reliable. The food contact surfaces are made of stainless steel, ensuring compliance with strict food hygiene standards. At the core of the production line is a continuous fryer, combined with the Urschel high-speed slicer from the USA and TSHS’s proprietary PLC control system. This ensures easy operation and smooth workflows while allowing flexible adjustments to frying temperature and time for optimal results. Three capacity options are available: 100kg/hour (PC100), 300kg/hour (PC300), and 500kg/hour (PC500), providing flexibility to meet market needs.

The line can be equipped with a dehydration device to remove excess moisture from potato slices before frying, saving thermal energy. A fine filtration system extends oil life, while built-in temperature and flow monitoring mechanisms ensure product consistency and safety. The CIP system improves cleaning efficiency, while smart monitoring, PQS, and AI quality prediction systems analyze production data in real-time, enabling precise parameter adjustments. These features achieve a high level of automation and efficiency, reducing labor costs and significantly improving production and product quality. To meet market demands, the production line can include a seasoning system for diverse flavor options and a high-efficiency de-oiling system to reduce excess oil for healthier chips. This creates a highly efficient, stable, and versatile potato chip production solution.

For more information, please feel free to contact us.

- Products

Continuous Automatic Fryer Equipment (FRYIN-302)

FRYIN-302、FRYIN-402、FRYIN-602

FRYIN-302 multi-functional continuous frying machine has the characteristics of two highs and three savings, and has many invention design patents in Germany,...

DetailsPotato Chips Production Line Manufacturer

TsungHsing Food Machinery is a potato chips production line machine manufacturer and supplier. TsungHsing Food Machinery (TSHS) is a manufacturer of snack...

Details

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Deep Fryer Machine | Snack Food Processing Equipment & Turnkey Project Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a food processing equipment supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 58 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.