Continuous Automatic Fryer Equipment (FRYIN-302)

FRYIN-302、FRYIN-402、FRYIN-602

Automatic Continuous Frying Machine, Conveyor Fryer, Continuous Fryer Machine, Conveyor Frying Machine, Machine for frying

FRYIN-302 multi-functional continuous frying machine has the characteristics of two highs and three savings, and has many invention design patents in Germany, in United States and in other countries. It has also won ISO9001, Taiwan Excellence Award... and others high-quality certifications. That allows customers to maintain excellent production quality while taking into account food hygiene and operational safety.

Introduction

The automatic continuous fryer is made of stainless steel according to the requirements of food hygiene regulations to ensure hygiene and improve equipment durability. Cleaning after use is the most troublesome thing to a continuous fryer, which often requires people to use more than 2 hours to clean the equipment. In view of the customer's experience and feedback, we have added the CIP automatic cleaning system, which can reduce the time for manual cleaning, and has a automatic lifting hood make it easy to clean the dead corners of the wall during cleaning, making maintenance more convenient. The hood can also prevent the quality of the product from being affected by the falling of contaminated materials during the production process.

The continuous fryer of TsungHsing Food Machinery uses a multimedia touchscreen to integrate the instantaneous current and voltage monitoring during various productions. The curve analysis analyzes various values, including the conveyor current display and curve, pump current display, curve and voltage display curves. The touchscreen can also check the abnormal alarm history records to understand the device usage. When the buzzer sounds, the touchscreen will show the cause of the abnormality and we can know how to troubleshoot from it. The automatic continuous fryer connection network of TsungHsing Food Machinery provides remote service, which can instantly monitor, modify, repair or update the system, repair software and other services, eliminating the time to wait for the original engineering staff to overhaul.

【FRYIN-302】Continuous Fryer Features

1. All food contact surfaces are made of stainless steel.

2. Automatic lifting hood makes it easy to clean and maintain.

3. CIP self-cleaning system.

4. Foolproof design of the startup sequence can help to avoid operational errors.

5. The Cooking oil loop is equipped with pressure protection to avoid pump from dry running.

6. Standard emergency stop button can immediately stop the operation of the equipment.

7. Automatic temperature control can freely adjust the temperature to the product that is being fried.

8. The combustion chamber is equipped with thermal protection to prevent the equipment from over temperature.

9. Queries related to the alarm history.

10. Adjustable frying time according to product characteristics.

The Fryin Series Oil Fryer of TsungHsing Food Machinery has the exclusive invention design "2 highs and 3 savings"

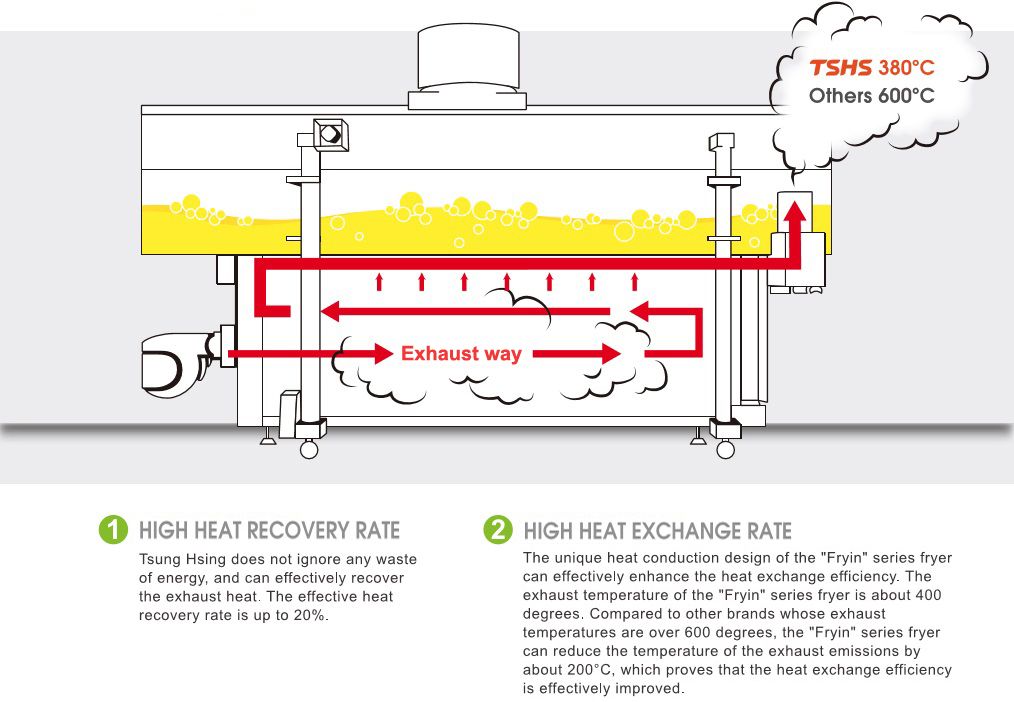

2 Highs: High heat recovery rate and high heat exchange rate. High heat recovery rate:

High heat recovery rate: Tsung Hsing does not ignore any Waste of energy, and can effectively recover the exhaust heat. The effective heat recovery rate is up to 20%. High heat exchange rate: The unique heat conduction design of the" Fryin" series fryer can effectively enhance the heat exchange efficiency The exhaust temperature of the" Fryin" series fryer is about 400 degrees. Compared to other brands Whose exhaust temperatures are over 600 degrees, the" Fryin" series fryer can reduce the temperature of the exhaust emissions by about 200°C, which proves that the heat exchange efficiency is effectively improved.

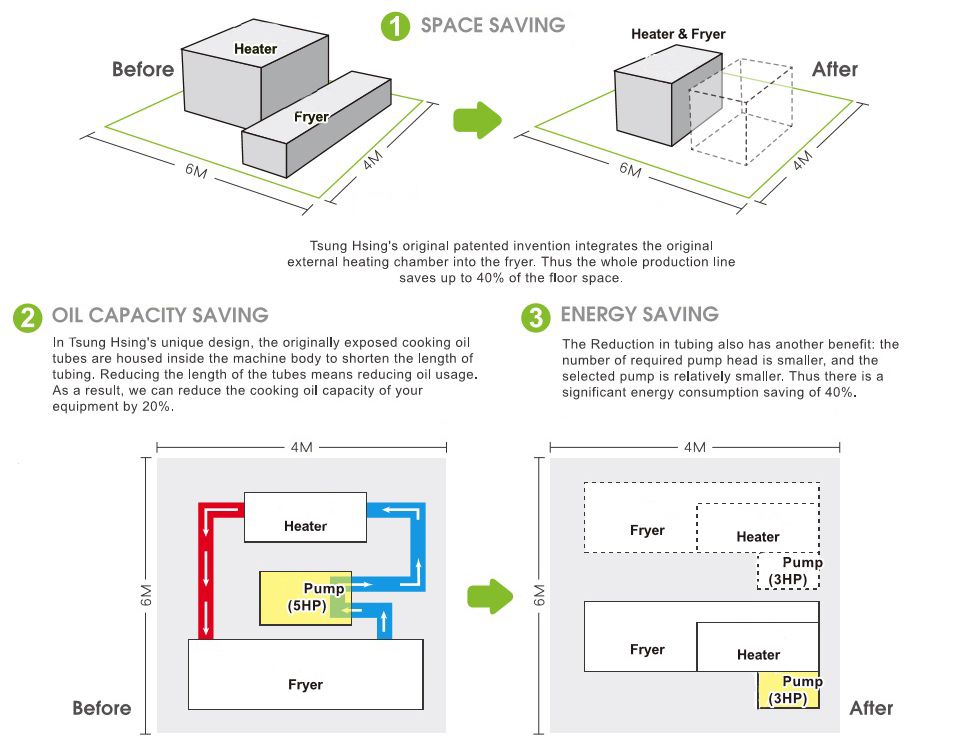

3 Savings: Space saving, oil capacity saving and energy saving.

Space saving, oil capacity saving and energy saving. Space Saving: Tsung Hsing's original patented invention integrates the original external heating chamber into the fryer Thus the whole production line saves up to 40% of the floor space.

Product Safety Mechanism

The automatic continuous fryer of TsungHsing Food Machinery is in compliance with CE safety regulations. There are many foolproof protection mechanisms in operation to avoid the risk of accidental contact caused by unskilled staff during operation. There is a set of emergency stop button on each side of the fryer. When any dangerous situation occurs during the operation of the equipment, all the actions of the equipment can be stopped immediately to avoid the deterioration of abnormal problem.

The automatic continuous fryer is equipped with circulating oil fluid pressure protection to avoid pump idling. The oil pipe is provided with a pressure protection mechanism: When there is no fluid in the oil pipe, the pump will not start; the burner is equipped with a thermal protection system to avoid the air-burning condition of the equipment; the automatic temperature control system, adjusting according to the frying temperature of different products and time to maintain the temperature of the oil.

Equipment Specifications | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mechanical Specifications | 【Metric Units】 | |||||||||

| Model | Size: mm | Effective Frying Space | Hp. | Calories | Cap. of. Edible oil | Production capacity | ||||

| L | W | H | green peas | peanuts | snacks | |||||

| FRYIN-302-E | 3450 | 2350 | 1950 | 2600*820*70 | 3 | 200000 kcal/1hr | 440LT | 110 kg/hr | 480 kg/hr | 300 kg/hr |

| Mechanical Specifications | 【Imperial Units】 | |||||||||

| Model | Size: in | Effective Frying Space | Hp. | Calories | Cap. of. Edible oil | Production capacity | ||||

| L | W | H | green peas | peanuts | snacks | |||||

| FRYIN-302-E | 135.8 | 92.5 | 76.8 | 102.4*32.3 | 2.25 | 793600 BTU | 116 gal | 243 Ib/hr | 1058 Ib/hr | 661 Ib/hr |

Equipment Information Of Related Product

- Heating energy: ①Liquefied Natural Gas (LNG)、②Liquefied Petroleum Gas (LPG)、③Diesel、④Heat Transfer Oil、⑤Steam

- Circulation System: High temperature resistant pump for 24-hour hot oil circulation.

- Control System: Digital frying temperature and frying time display.

- Filtering System: ①The continuous coarse residue filtering system, which can filter out the fried residue to extend the life of the frying oil, ②Scraping at the bottom to remove residue which has sedimentation characteristics.

Peripherals / Accessories

- Feeding M/C.

- Online Fine Filter.

- De-oiling M/C.

- Vacuum Oil Water Separator.

- Oil Cooling System.

- Oil Drum Insulation / Cooling System.

- Seasoning System.

- Previous Stage Shaping System.

Applications

- Meat And Seafood:chicken wings, drumstick, fried chicken, chicken fillet, crispy sparerib, chicken skin, cuttlefish balls, tempura, carrotcake, dumpling, potato croquettes, spring rolls

- Frozen Food:chicken nuggets, french fries, fish bean curd, hot pot ingredients, ther semi-ripe frozen foods

- Snack Food:shrimp cracker, nuts, bean, potato chips, banana chips, noodle snack

- Vegetarian Food:plant meat,vegetarian meat, tofu, tofu skin, vegetarian noodle wheel

- ※FRYIN-302 continuous frying machine is suitable for frying various products from flakes, bars, granules, and irregular products.※

- Cuttlefish Balls

- Dumpling

- Spring Roll

- Tofu

- Croquette

- Chicken Nuggets

- Chicken Skin

- Tempura

- Carrotcake

- Shrimp Cracker/Puffed Foods

TSHS provides the consultant food solutions

Tsung Hsing has more than 50 years of experience in producing continuous frying machines. The fryer equipment produced from TSHS has been sold global market, and we have constantly been innovating and changing. With automatic control and system application, the FRYIN-302 continuous fryer can be used single or combined into a production line for continuous production.

If you have a fryer requirement, please fill out the inquiry form below.

We will contact you as soon as possible.

- Related Products

Small Size Continuous Conveyor Fryer Equipment (FRYIN-201)

FRYIN-201

FRYIN-201 is a small-size continuous conveyor belt fryer. Which has three features: small volume,...

DetailsHeavy Capacity Continuous Automatic Fryer Equipment

FRYIN-802、FRYIN-1103

The continuous high-output fryer is suitable for a large number of products, such as beans,...

DetailsContinuous Microwave Hybrid Fryer Equipment

The microwave frying is a new type of application in food heating. In addition to use the heat...

DetailsContinuous Deep Oil Fryer Equipment for Syrup Coating Product

The continuous fryer for syrup products is suitable for the fried foods with sugar-coated,...

Details- Videos

- Finished Product Gallery

- Finish Products – Banana Chips

- Finish Products – Crack

- Finish Products – Crisp Chili

- Finish Products – Fried Steak

- Finish Products – Gralic Slices

- Finish Products – Green Bean

- Finish Products – Maruku

- Finish Products – Pellet

- Finish Products – Potato Chips

- Finish Products – Shrimp Cake

- Finish Products – Sweet Potato Chips

- Finish Products – Sweet Potato Slices

- Product catalog Download

FRYIN Series_FRYIN-302 Continuous Fryer Digital Catalog

FRYIN-302 multi-functional continuous frying machine has the characteristics of two highs and three savings, and has many invention design patents in Germany,...

Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Continuous Automatic Fryer Equipment (FRYIN-302) Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Continuous Automatic Fryer Equipment (FRYIN-302) supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 58 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.