How a Green Pea Production Line Creates Market Competitiveness

"Unveiling the Green Pea Production Process: Every Step from Farm to Table"

Green peas, a widely loved ingredient for healthy snacks, undergo a meticulous and precise production process. Cultivation begins with selecting farmland that has well-drained soil and ample sunlight, ensuring optimal growth conditions. Farmers carefully manage irrigation, fertilization, and pest control to maintain the quality and yield of the peas. Once the green peas reach maturity and develop a plump texture, they are harvested using either mechanized or manual methods. The freshly harvested peas then go through rapid sorting, cleaning, and shelling to preserve their freshness and purity. Advanced processing equipment allows for dehydration, roasting, or frying, followed by the addition of seasonings to create the crispy and flavorful snacks that consumers love. Every step in this process relies on professional expertise and high-quality machinery to ensure that each green pea maintains superior taste and quality.

"Global Market Trends of Green Peas: The Rise from Traditional Ingredient to Innovative Snack"

In recent years, the global demand for green peas has been steadily increasing as they transition from a traditional food ingredient to an innovative snack. With the rise of health-conscious eating trends, green peas—rich in plant-based protein and dietary fiber—have gained significant consumer attention. Food manufacturers are actively developing diverse products such as roasted peas, crispy chips, and seasoned snacks to meet market demands. Particularly in Asia and Western markets, green pea snacks have become a highlight due to their crunchy texture, diverse flavors, and nutritional benefits. With advancements in processing technology and the widespread adoption of automated equipment, production efficiency and product quality have significantly improved, further enhancing the market competitiveness of green pea products.

"Efficient, Stable, and Energy-Saving: The Best Choice for Green Pea Production—TSHS Food Machinery"

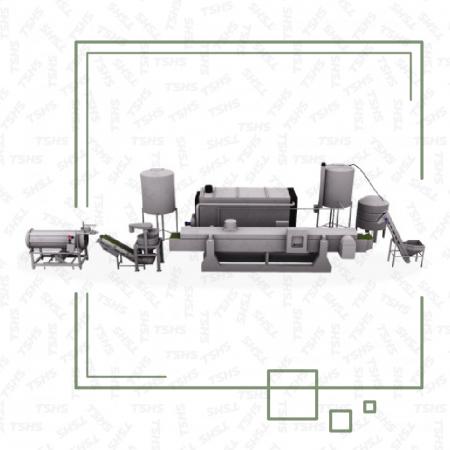

TSHS Food Machinery specializes in manufacturing green pea production line equipment, offering automated, high-quality, and high-yield solutions. Green pea snacks, such as garlic-flavored peas, are highly popular in the global market. To meet growing demand, TSHS has developed a complete and highly efficient production line that includes soaking, dehydration, screening, precise feeding, frying, de-oiling, and seasoning—all fully automated processes that ensure product stability and superior quality at every stage.

This fried green pea production line is designed for high output and consistent quality, with production capacities ranging from 150 kg/h (TSHS-GP-150) to 700 kg/h (TSHS-GP-700). The continuous fryer features a temperature control system that prevents peas from bursting during frying, ensuring uniform appearance and texture. The entire production line is engineered for energy efficiency, oil savings, and reduced labor costs, while its food-grade safety and hygiene design ensures compliance with international standards. Whether in terms of production efficiency, product quality, or market competitiveness, TSHS Food Machinery’s green pea production line is the ultimate choice for food manufacturers.

- Products

Continuous Automatic Fryer Equipment (FRYIN-302)

FRYIN-302、FRYIN-402、FRYIN-602

FRYIN-302 multi-functional continuous frying machine has the characteristics of two highs and three savings, and has many invention design patents in Germany,...

DetailsGreen Pea Production Line Manufacturer

TsungHsing Food Machinery is a green pea production line machine manufacturer and supplier. TsungHsing Food Machinery is a professional manufacturer of Frying...

Details

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Deep Fryer Machine | Snack Food Processing Equipment & Turnkey Project Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a food processing equipment supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 58 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.