Continuous Microwave Hybrid Fryer Equipment

Microwave Frying Equipment, Microwave Mixing Fryer, Continuous Microwave Frying Equipment

The microwave frying is a new type of application in food heating. In addition to use the heat energy by oil to heating and ripening the fried products from the outside to inside. Also can used microwave function, it can heat the fried products quickly inside and outside at the same time. And the experiments result in the microwave frying achieve to increase the cooking speed efficiently.

The continuous microwave fryer is suitable for frying a variety of products. The feature of microwave adopts internal and external heating. It can overcome the products that require long-term frying, such as meat products or products with thicker sizes. Over all, the microwave frying can make the frying time shorten effectively.

Moreover, the continuous fryer from TSHS meets three points: food hygiene law, simple operation and safe device alarm. The microwave frying continuous improved and innovation. TSHS R&D team aim to become the expert who is specialized in microwave technology in frying.

Introduction

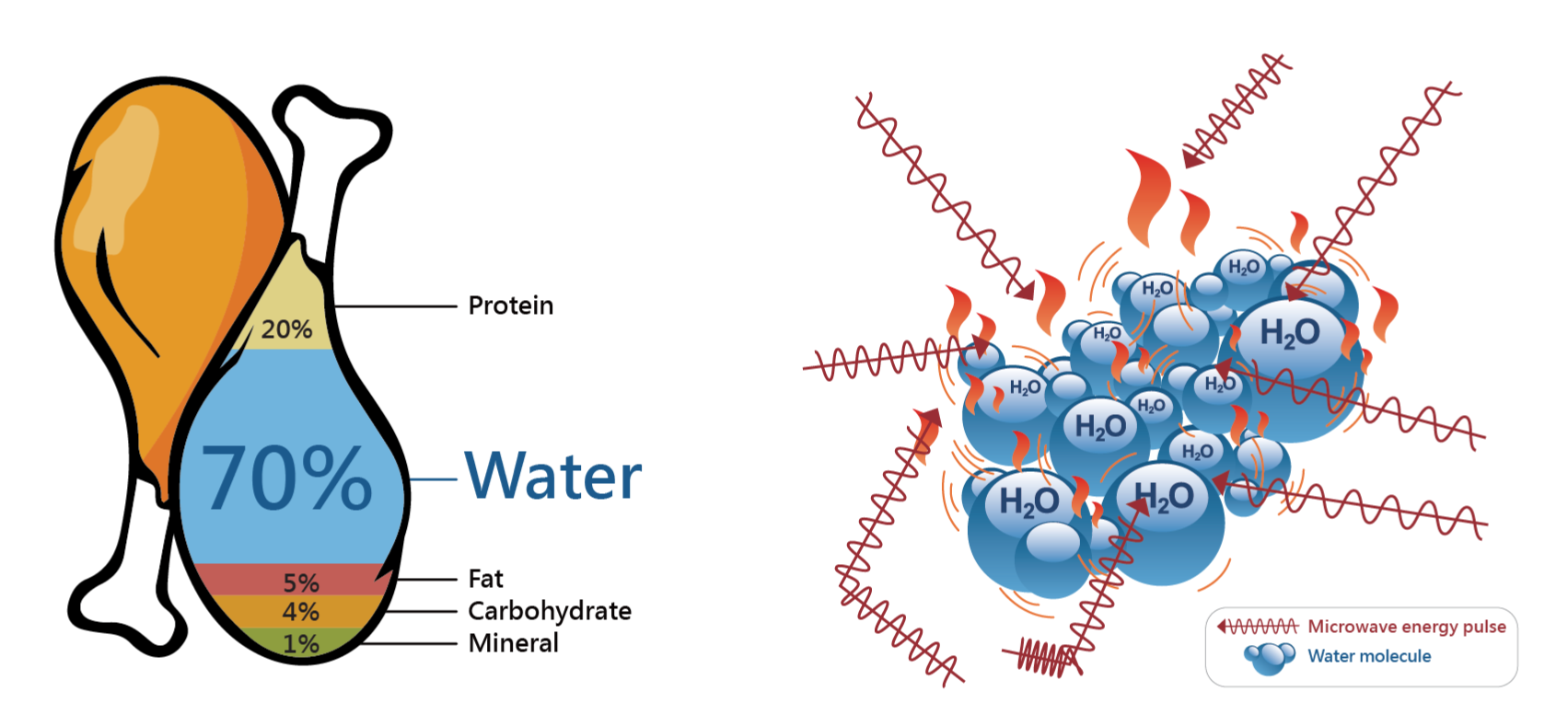

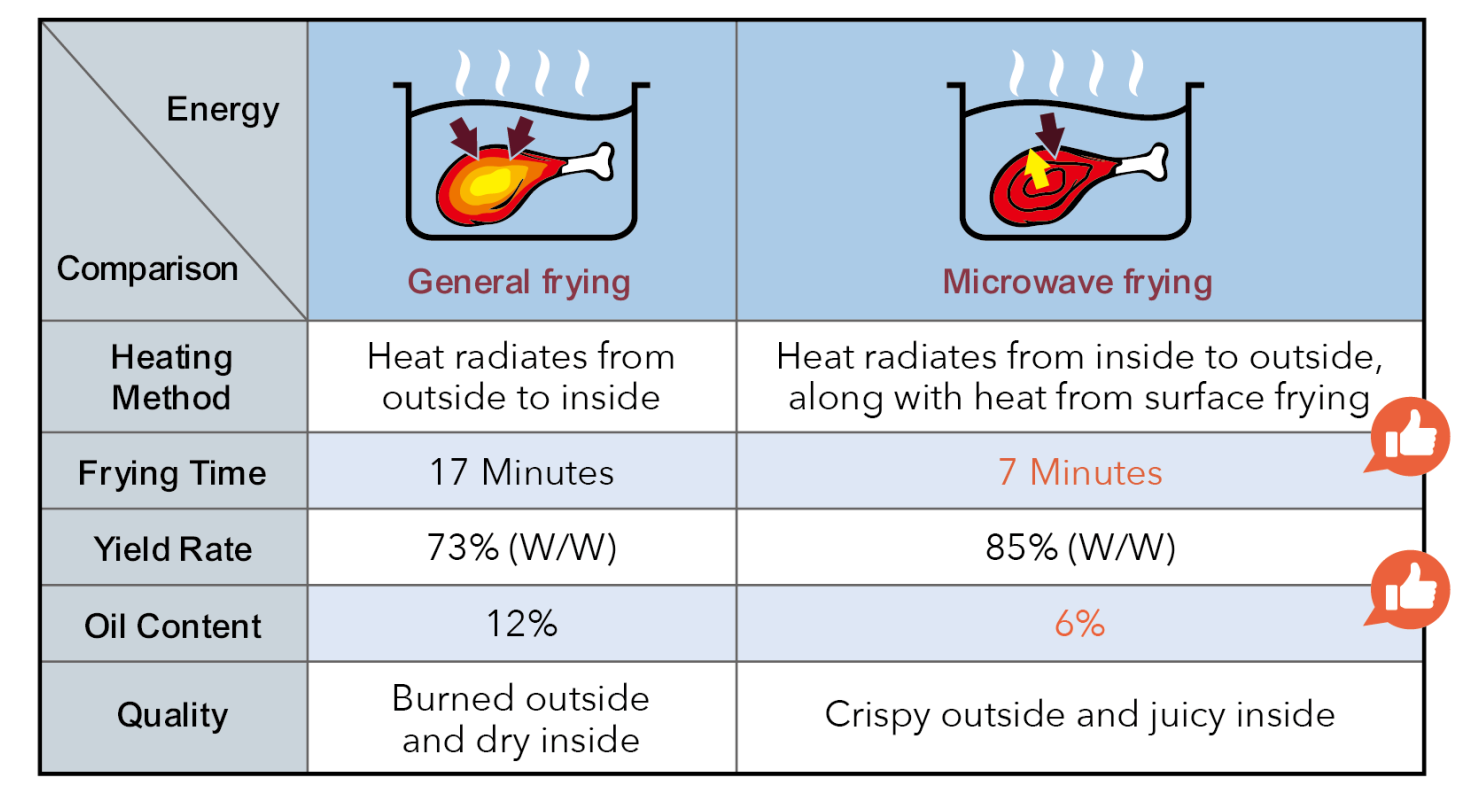

The continuous microwave hybrid fryer uses microwave mixed frying heating to overcome the problem of traditional fried foods, which are cooked on the surface but not well inside. For Large pieces of food such as chicken legs and pork blocks, the heating time can be shortened by 70 - 75%, the weight loss is reduced by 30 - 40% compared with the traditional frying process, the oil absorption rate is reduced by 40%, the product is juicy and the taste is better. It can achieve the advantages of golden appearance and crispy skin. The microwave fryer of TSHS uses the high efficiency continuous oil fryer (you can refer to FRYIN fryer of our company to see the style and appearance), adds microwave launch cavity and microwave transmitter above the frying tank. The microwave is heated by the second energy source, and the depth of the explosive is rapidly heated and ripened. The microwave emission power can be configured according to the frying requirements to achieve the fries ripening optimization. The middle section of the frying tank is a microwave section, and a microwave anti-leakage section is provided at the inlet and the outlet to prevent human body damage caused by microwave leakage. The microwave transmitter and microwave controller are modularized and easy to maintain. It is easy to operate and easy to control by user-friendly design. The use of microwave hybrid heating will be an innovative processing method different from the traditional heating method. It can be expected to improve product quality, create a new and different taste of the product, and hope to get a new process to achieve product innovation. Referring to the microwave heating principle, there are many more professional explanations in theory. To put it simply, the molecules in the product are oscillated by microwave, and the molecular friction heat generation is the source of the core heating principle. In particular, the shock is caused by the water molecules in the product.

Microwave Frying Testing Video

Microwave Fryer Features

1. All food contact surfaces are made of stainless steel.

2. Frying machine hood and conveying truss are easy to maintain and clean with screw lifting.

3. The frying tank, the heating pipe and the inside of the hood of the fryer have a CIP automatic cleaning system.

4. The burner ignition start sequence has a foolproof design to avoid malfunction.

5. The oil circulation tubing is equipped with pressure protection to prevent the pump from idling or oil-free ignition in the tubing.

6. The left and right sides of the bomber are set up, The emergency stop button, set on the left and right sides of the bomber, can stop the operation of the equipment immediately.

7. The automatic temperature control system, adjusting according to the frying temperature of different products and time to maintain the temperature of the oil.

8. Warning of Over or Less Temperature.

9. The exhaust gas is equipped with overheating protection to avoid overheating of the equipment.

10. Alarm history record query.

11. Adjustable frying time according to the features of the product.

12. There are microwave anti-leakage sections at the entrance and exit to prevent human body damage caused by microwave leakage.

13. The microwave transmitter and microwave controller are modular and easy to maintain.

14. User-friendly design, simple and easy to control.

In addition, it should be noted that: microwave heating is not heating from the inside out, the correct explanation is heating inside and outside at the same time. This point must be specifically explained.

Advantages of microwave frying:

1. Shorten the oiling time.

2. Food is healthier because of the fry contains less oil.

3. The look and taste are better because of the fry is soft, tender and won't dry.

4. If the fried food is meat, it contains more gravy and it becomes more delicious.

5. It can save raw material costs by oil saving.

6. Small size and large output equipment.

7. The equipment takes up little space and can make full use of the plant space.

8. Microwave accessories are modular to have efficient maintenance.

Microwave Frying vs. Traditional Frying

Product Features

- Differences:

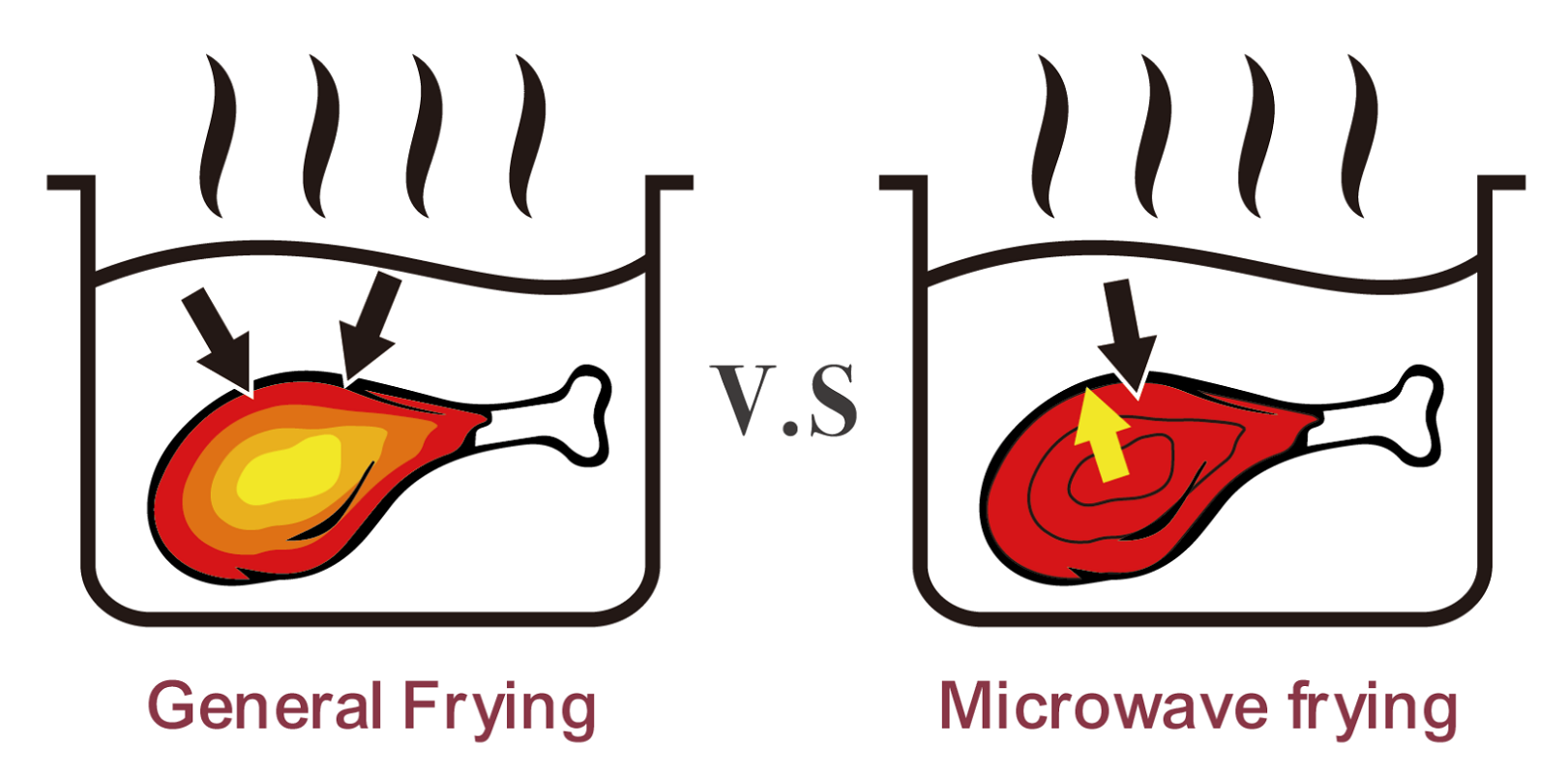

- 1.1The general traditional continuous fryer, whether it is the inner furnace or the outer furnace heating method, the frying oil is heated by the heater, the frying oil is heated to the frying temperature, and the hot frying oil is circulated to the frying tank. The fry is put in from the inlet, heated and ripened, and discharged from the outlet of the fryer. The heat transfer of the bomb is to transfer the temperature to the center of the fry by the appearance, and then ripen the fry.

- 1.2.In addition to the above-mentioned frying oil heating and ripening method, microwave hybrid frying uses microwave-assisted heating to simultaneously heat and ripen the fry from the center point to the inside and outside of it.

Applications

- Meat And Seafood:chicken wings, drumstick, fried chicken, chicken fillet

- ※Microwave hybrid continuous fryer is suitable for all-round fried foods that require shorten frying time.※

TSHS provides the consultant food solutions

Tsung Hsing is a professional microwave fryer manufacturer and supplier. The specifications of the microwave fryer provided by Tsung Hsing are the same as the specifications of the others fryer. Please refer to FRYIN-201, FRYIN-302, FRYIN-402, FRYIN-602, FRYIN-803 specification dimensions. Different customized planning and design can be provided according to customer products need and output requirement.

If you have a fryer requirement, please fill out the inquiry form below.

We will contact you as soon as possible.

- Related Products

Small Size Continuous Conveyor Fryer Equipment (FRYIN-201)

FRYIN-201

FRYIN-201 is a small-size continuous conveyor belt fryer. Which has three features: small volume,...

DetailsContinuous Automatic Fryer Equipment (FRYIN-302)

FRYIN-302、FRYIN-402、FRYIN-602

FRYIN-302 multi-functional continuous frying machine has the characteristics of two highs and three...

DetailsHeavy Capacity Continuous Automatic Fryer Equipment

FRYIN-802、FRYIN-1103

The continuous high-output fryer is suitable for a large number of products, such as beans,...

DetailsContinuous Deep Oil Fryer Equipment for Syrup Coating Product

The continuous fryer for syrup products is suitable for the fried foods with sugar-coated,...

Details- Finished Product Gallery

- Product catalog Download

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Continuous Microwave Hybrid Fryer Equipment Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Continuous Microwave Hybrid Fryer Equipment supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 58 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.