Continuous Deep Oil Fryer Equipment for Syrup Coating Product

After Syrup Coating and Frying Machine、Continues Syrup Coating Product Fryer, Continuous Deep Oil Fryer for Syrup Coating Product

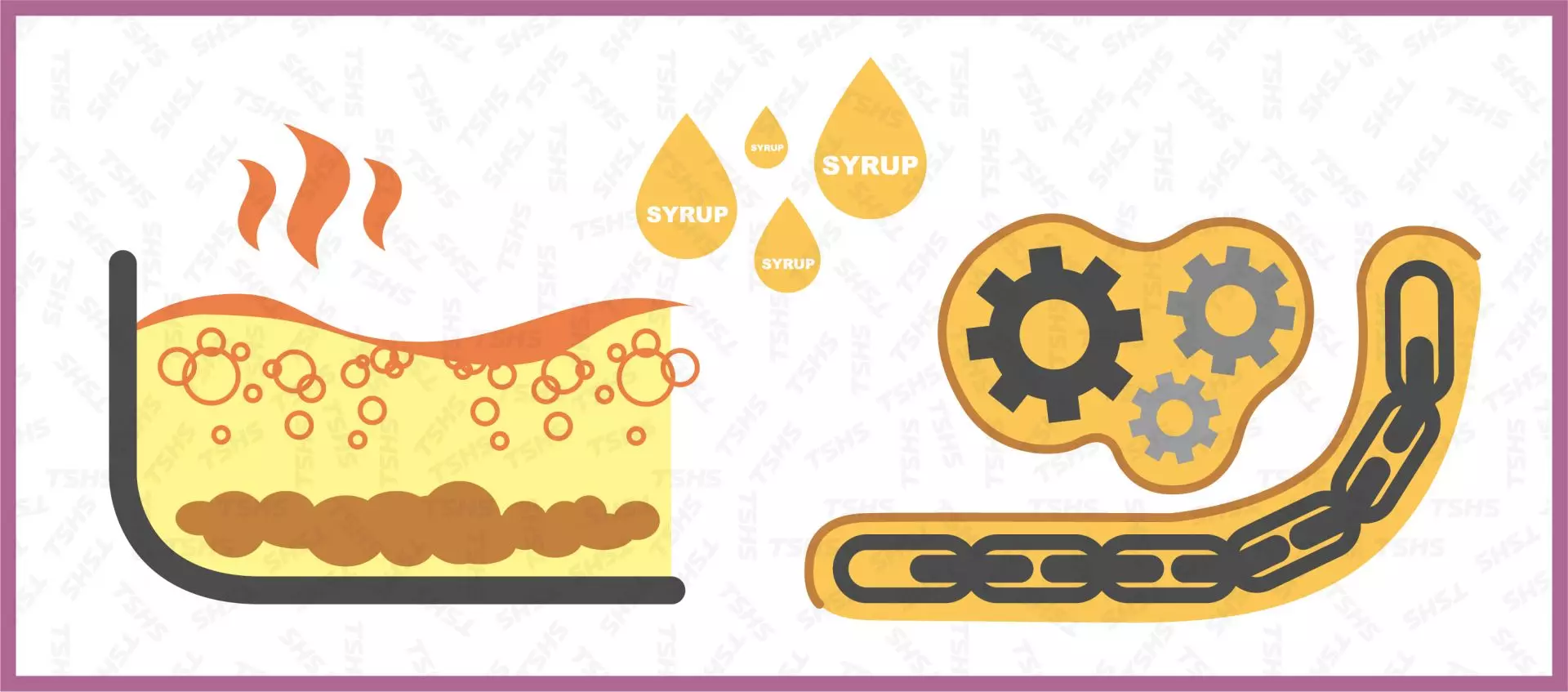

The continuous fryer for syrup products is suitable for the fried foods with sugar-coated, flour-coated, and paste-coated. Our team recommended using a heat transfer oil heating system to provide a stable heat source effectively and make the syrup food fried evenly when frying. The caramelized solids are produced by sugar and water combined. To reduce the sticky dregs attached to the equipment, Tsung Hsing developed the exclusive design that the sticky impurities are sediment to the machine bottom to maintain the machine production operated regularly, so that fulfill the needs of continuous production.

Banana Chips Testing Video

Heat Transfer Oil Heating System Advantage/h5>

1. All food contact surfaces are made of stainless steel.

2. Space-saving.

3. Furnace coils are heated evenly by multiple tubes which increase both heat transfer area and efficiency.

4. With relevant safety alarms and automatic/manual stop protection.

5. Automatically continuous production

6. Special three-in-one design with optional heating systems according to customer’s requirements.

7. Reducing the condensed impurities due to the mixing of sugar and oil and extending equipment life.

Banana Chips Testing Photo

Traditional Frying Way

When the sugar water of the sugared food is fried at high temperature, it will produce the principle of carbonization; also known as caramelization, the caramelization reaction will produce a large amount of residue, which makes the rapid increase of the acid value of the oil, thereby reducing the life of the oil, and the severe caramelization will condense and adhere to the mechanical equipment, causing the conveyor chain to break or deform, which may easily cause equipment damage. In order to reduce the damage of equipment, the traditional method chooses to use the fryer and batch processing method, manual feeding and long-term frying production, and it takes time to cleaning and equipment maintenance, which is inefficient in the production process. And it takes a lot of manpower and space, and the production capacity cannot meet the continuous mass production demand.

Peripherals / Accessories

- Quantitative Feeding M/C.

- Vibration Oil Dripping.

- Cooling Conveyor.

- Syrup Pouring M/C.

Applications

- Sugared Snack Food

TSHS provides the consultant food solutions

Tsung Hsing(TSHS) is a professional deep fryer manufacturer with 60 years of experience. Our team have successfully developed a multifunctional continuous conveyor deep fryer. The food contact surfaces are made of 304 stainless steel and have been patented in the United States, Germany, Thailand, Indonesia, Malaysia, and China. Currently sold in over 65 countries worldwide.

If you have a fryer requirement, please fill out the inquiry form below.

We will contact you as soon as possible.

- Related Products

Small Size Continuous Conveyor Fryer Equipment (FRYIN-201)

FRYIN-201

FRYIN-201 is a small-size continuous conveyor belt fryer. Which has three features: small volume,...

DetailsContinuous Automatic Fryer Equipment (FRYIN-302)

FRYIN-302、FRYIN-402、FRYIN-602

FRYIN-302 multi-functional continuous frying machine has the characteristics of two highs and three...

DetailsHeavy Capacity Continuous Automatic Fryer Equipment

FRYIN-801、FRYIN-803、FRYIN-1103

The continuous high-output fryer is suitable for a large number of products, such as beans,...

DetailsContinuous Inner-Furnace Fryer (FRYIN-K Series)

FRYIN-302K、FRYIN-402K

The FRYIN-K Series Continuous Fryer is engineered to comply with European CE safety regulations...

DetailsContinuous Deep Oil Fryer Equipment for Syrup Coating Product

The continuous fryer for syrup products is suitable for the fried foods with sugar-coated,...

Details- Videos

- Finished Product Gallery

FRYIN-201 Small-size Continuous Fryer

Enter the continuous production market at an affordable price. The "small volume, space-saving" FRYIN-201 fryer. Suitable for small food industry, central kitchens, restaurants, food stores, schools, etc.

Over 50 Years of Continuous Deep Oil Fryer Equipment for Syrup Coating Product Supply | TSHS

Based in Taiwan, since 1965, TSUNG HSING FOOD MACHINERY CO., LTD. is a Continuous Deep Oil Fryer Equipment for Syrup Coating Product supplier in snack foods industry.

500 food processing production lines sold in 65 countries, TSHS is a food machine expert with over 60 years of experiences. CE certified, reasonably priced food processing machinery are industrial fryers, oil heating systems, seasoning tumblers, liquid mixer machines, liquid sprayer machines, etc.

TSHS has been offering customers high-quality food processing machines for green peas, nuts, potato chips, grain puffs and corn puffs, with total snack foods solutions. They represent trust, specialty, high-quality and safety specialization, which is where their name TSHS came from.